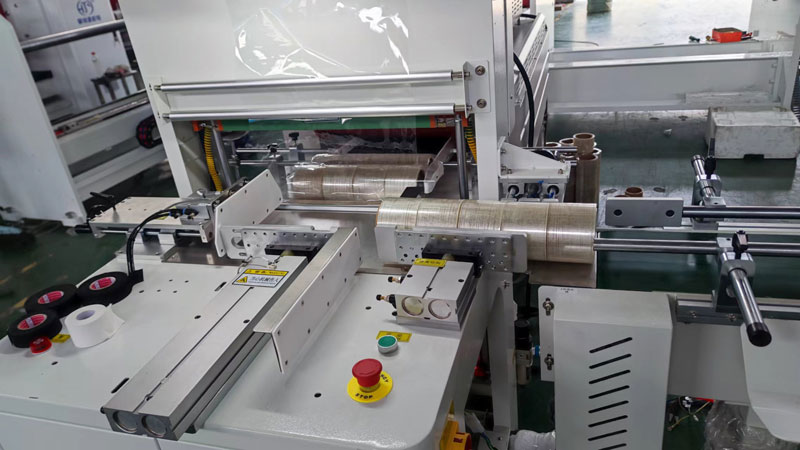

PE film heat oven tunnel thermal Bopp tape shrink wrap packing machine

Fully-auto Sleeve Sealer& Shrink Tunnel is designed for a single object or objects with paper tray.

This machine can be connected with other production machines with the function of automatically feeding, wrapping, sealing;

shrinking and cooling, unmanned assembly-line to realize unmanned operation;

introduces internationally advanced technology and production process which can automatically calculate the daily output;

The performance is reliable;

Induction film-feeding greatly reduces film waste;

Imported Autonics digital temperature controller with precise temperature shows directly when it is sealing;

Stepless mechanical speed adjustment device regulates the speed of the feeding conveyor;

The usage of Siemens PLC and touch screen achieves the integrations of mechanism, electricity and pneumatic;

A specially designed three-piece sealing knife makes sure solid sealing line, no cracking and anti-stick;

using imported double air circulation motors, so that the hot air in the oven can spread more evenly to get a good shrink effect;

Large amount of cooling air flow, rapidly cooling the product after heat shrinking;

The use of Frenchr frequency inverter controls transmission speed which has the function of infinitive speed;

For drinks, beer, mineral water, cans, glass bottles with paper- tray and cardboard boxes integrated or single product's shrink-wrapping